The CLC Passagemaker starts to come together.

Blog time – Early September 2024. I now write these posts against the background of what I can only call a tyrannical situation in the UK. As I write our prime minister has just announced emergency measures to free up prison overcrowding while at the same time putting pressure on the legal system to convict more people for social media related crimes – either sharing tweets or making ‘incorrect’ posts on Facebook. At the same time he seems intent to make any comment or discussion about Islamic based terrorism a hate crime and his home office minister seems set to try the same thing with misogyny. I continue in trying to predict and warn the British public what is likely to be his next move with a weekly post just on this subject and even now I feel that I have to be extremely careful in what I say or write.

Lots of sanding done and the first coat of primer on.

Pathfinder.

Today, i would describe the Pathfinder project as being over time, a long way over budget and over there as it now lives on it’s trailer while I work on the CLC dinghy out in the open utilizing my old build bench. I’m working on the Pathfinder again this week – a quick perusal of the inside of my shed door reminds me what I should be working on. This week i’m going to finish attaching the boom gallows stanchion mounts and hopefully getting some timber to make the actual cross member out of ; a smaller job this week is that i’m going to change the jockey wheel on the trailer because the yard work here has slowly chewed the old one up.

CLC Pasagemaker

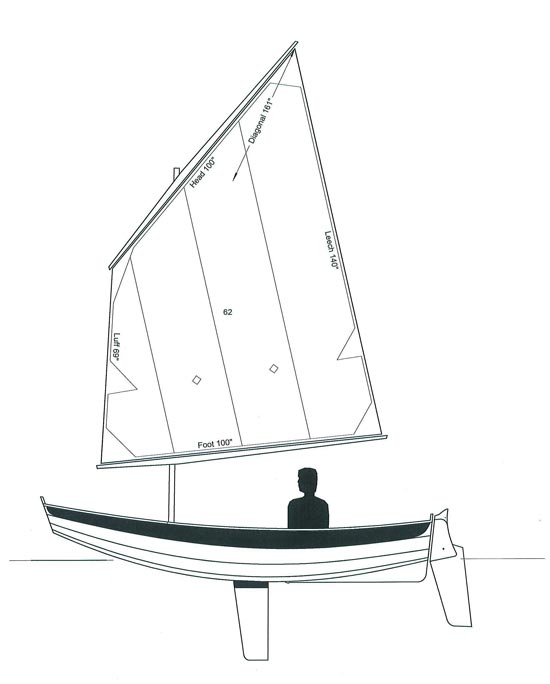

My main attention now is on refitting and fitting out the little Passagemaker and in comparison to the over schedule and over budget Pathfinder I intend to do this one quick, cheap and dirty in boatbuilding terms. Right now i’m working on the outside paint job – it’s going to get several coats of primer and then a heavy rub down with some wet and dry sandpaper used wet. After that and it’s topcoat (i’m only going to use one pack enamel) we will flip her over and refinish the inside while I source materials for the spars, have a sail made and hopefully find a secondhand trailer.

The expression ‘quick,cheap and dirty’ might not be quite what you think – I have also heard it said as ‘dirty deeds done cheap’ although i’m told that that is also the name of some obscure Australian rock band. At my end of the backyard boat ecosytem it often meant a boat thrown together quickly and only using cheap, or at least not staggeringly expensive, materials. What it doesn’t mean is work done roughly or carelessly : in my case, with the CLC dinghy, I was at least 3 days trying to sand the hull so that I get a better chance of giving it a fair finish. The cheap in this sense is that I already have a supply of sanding discs and half a tin of dark primer left over from another project thus cheap is mostly about seeing what I have got kicking around that I can use again.

Available materials technology.

I have a good sailing friend down in NZ who prefers the term available materials technology when he is making best use out of stuff that he has laying around or which is somehow found rather than purchased at high cost. His own variant is that there is usually a nice or approved way of doing something but often there is a choice that isn’t as yachtie=smart but works just as well and at a lower cost. In my first week of sourcing parts and materials I came across this with the fact that the first thing I need to build is a mast for the little dinghy. The approved and smart choice is to build a square section wooden spar with the edges rounded off, i’m quite capable of doing that and in fact I contacted the marine timber merchant to cost up the timber for me but then rejected their quote ; not so much the price of the material (clean Douglas Fir) but the huge cost of delivery (their quote was £100 !).

My alternative was to have a think about ways in which I could make a viable mast out of more cheaply available materials even if it meant altering or adapting parts of the boat to do so – the obvious place to start was readily available round section alloy tube and the cost difference was something like £60 for a length of tube or nearly £300 for the timber. The use of that material creates 2 new problems, one lesser and one greater – the greater being that I am not sure about the strength of 16g tube and where using 10g would be too heavy. The solution seems to be in accepting that I will have to build an internally sleeved mast and the lesser problem is that I will have to fit a round peg (mast) in a square hole !.

My three challenges this week were : firstly the mast and I think I have solved that one with the use of available materials technology, the second one was to find a sailplan drawing and then ask my usual sailmaker for a quote – ok so done with that one. The third and potentially difficult or expensive problem was to source a road trailer and trolly : a new one is clearly outside my budget and then, hey ho, I find 2 on Ebay – only one is advertised as being in Kings Lynn (actually Brancaster which is another 60 miles further) and the other one I think is in Manchester except that the owner won’t tell me it’s whereabouts so it’s difficult even to plan a trip – one journey we know would be a 700 mile round trip and a trip to Manchester is around 260 miles each way.

Oh…..and it didn’t turn out as black because I still had some light grey left.