Time to rig the Pathfinder.

First, the new video version.

Setting up the trailer has taken a lot longer than I expected but it hasn’t been helped by the trailer company not sending the last order because it contained a can of galvanizing spray paint and apparently their courier won’t or can’t transport it. That the local Toolstation took my order and delivered it the next morning is kind-of funny. So, aside from needing a couple of tie down points bolted on, sorting out the boat insurance and then actually strapping her down (the boat….not my girlfriend) we’re just about ready to go out and cause chaos in the Cornish lanes. I am working on one more trailer issue and that is an experimental single side docking arm to make it much easier to land the boat in the same position on the trailer every time we recover her.

Meanwhile it’s high time that I got on and rigged the boat.

I had intended to be doing all three current jobs in parallel at the same time but setting and tamping 300 Kg of Tarmac really sapped my energy and I was almost at headbanging stage with the rigging company on the east coast who were supposed to be making up the standing rigging – can’t exactly just walk in there and have a word with the rigger either. Today, instead of trying to get the first rigging job sorted online we did the obvious thing and that was to drive down to QAB (Queen Anne’s Battery) and just go talk to one of the riggers at Allspars. Why I didn’t use a local rigger in the first place I have no idea – we actually have two decent rigging shops within driving distance and because we’re off to Mylor (Falmouth area) this week I thought of them but Plymouth is nearest and it’s a small job for them.

For those that remember we actually had the mast up once at the end of last year just on temporary rope stays, and that really just to allow me to measure up for the standing rigging but with higher priory jobs to do the rigging job kept slipping down the ‘door’ list.

Rigging plan.

As you can see the mast is in a well supported tabernacle and is going to be triangulated by a single shroud each side laced to the Bronze chainplates and both pulling against the inner forestay as seen in the photograph above. The inner forestay only keeps the mast up unless I chose to have a heavy weather staysail later on – in normal sailing conditions the jib will free-fly off the end of the bowsprit or if I have some spare cash be set on a simple jib furler. As of today the riggers (Allspars) are making up a pair of wire rope shrouds, a forestay and bobstay – the bobstay will have to be easily removeable because it will foul the trailer winch strap while towing. I did wonder about having to remove the bowsprit for trailing but because I had to move the boat aft on the trailer a bit it’s now within the length of the draw bar and not trying to poke through the back window !

In the future it’s possible that I might want a longer bowsprit to help me balance the rig as my first set up will be with some positive rake – nothing technical – I just like the look of raked masts, and that it might be fun to fly an asymmetric spinnaker or reacher off the bow.

Cordage that I bought for Inanda and never used….some of the Dyneema has been doing duty as my hauling tackle line.. I favor high-tec low stretch rope for the jib and that’s likely to be hoisted on a 2 ; 1 purchase and the same tackle will probably be part of raising the mast. Anyway, enough talk and lets have at it.

This week we collected the (made up) standing rigging plus some extra cordage from Allspars riggers down in Plymouth and i’m surprised to say that, for once, everything fitted and the day went by with very little swearing so just as the sun disappeared behind the high ground and it got really cold I’d had the mast up and down with it’s rigging several times and even got as far as adding blocks , reeving halyards and hoisting the gaff yard.

I was expecting a bit of difficulty hoisting the rig because it is, after all, an 18 foot wooden pole mast, and although built as well as I could it’s still got a bit of heft to it. To be honest though, once I had it’s pivot bolt through the tabernacle and a 3 part hoisting tayckle attached to the bowsprit it went up cleanly first time – all I had to do was just slacken off my pre-set shrouds to let the mast rotate to full height. If it looks like it has a bit of rake then yes it does but the drive is also quite sloped at that point and I think the jockey wheel was a bit high ……must say though that I just like the look of well raked masts and yes I may have to alter things to get the boat to balance correctly.

At this point I can do the pivot and hoist myself but it does need an extra person to help with lowering it because of the way my hoisting tackle works (with a jammer) at the bow. When I can get the parts I will set up the hoisting tayckle so that I can run it up the mast with the 2 part jib halyard as and when I need it and it’s tail will come back to a cleat or jammer on the cuddy roof. An interesting thing is that I left the rig up overnight for the first time and left it set up quite ‘hard’ ie firm. This morning I noticed that the shrouds had slacked off just a bit which suggests that I have stretched either the wire rope of the shrouds or their lashings…..whatever, all it needed was a tiny bit of extra heave at it’s inner forestay and it’s all good again.

Day 2,

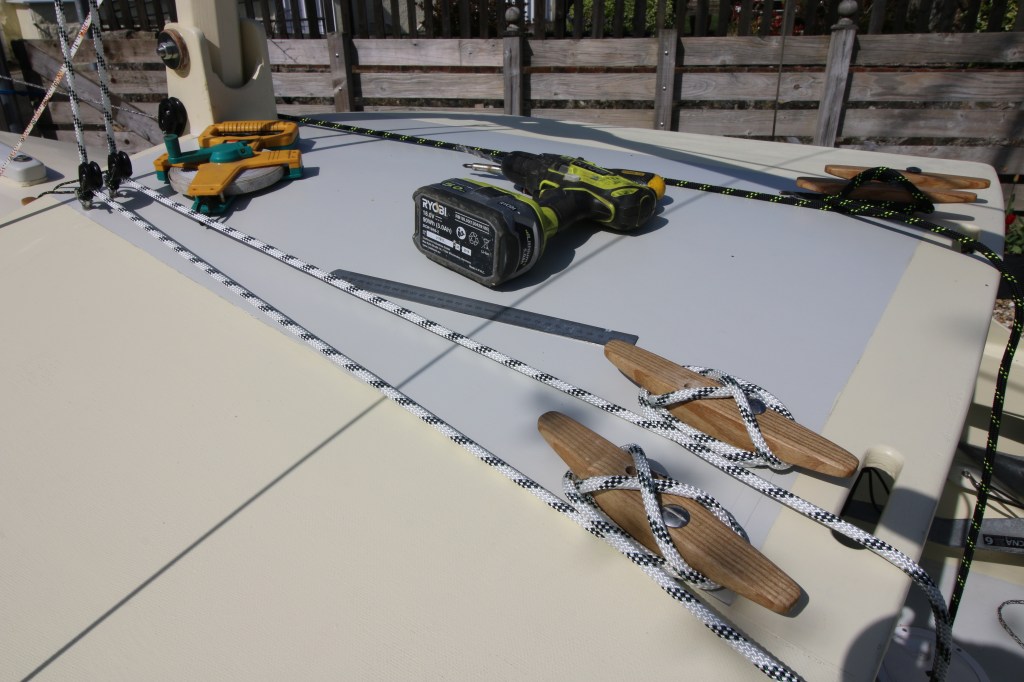

It’s been another long day and iv’e had the mast up and down several times as I add halyards one at a time and then set up the deck gear for them at the same time before moving on to the next one. Day two didn’t go as well in that I made some basic ‘noob’ errors when measuring and drilling for the eyebolts and halyard cleats – all of the halyards are going on my simple Ash cleats rather than expensive jammers and I managed to make a mistake with my drill in that I accidentally broke through the ply face a couple of times and made a bit of a mess….some epoxy work to do !

Right at the end of day two I attached all three of my working measuring tapes to the tack, throat and peak and measured off for the mains’l. The boat is almost but not quite a standard Pathfinder sloop but just different enough with the cuddy and mast position to warrant measuring everything and having the 2 working sails custom made. Comparing my measurements against the plans is, i’m glad to say pretty close so I should be in the ballpark in terms of boat balance. By the end of this week (Easter week) I may even have the sails on order which feels like a huge step forward….in the meantime I continue to add more and more detail and my bits boxes are slowly emptying of cleats, blocks and essential cordage.

Looking good Steven! When you are finished you can just jump on a plane and come across the pond to help me finish mine. FYI I built a furler to Joel Bergen’s design for very little money and it seems fine. My local tooling supply house has nylon thrust bearing but I used Oilite bronze washers which seem fine. Time will tell.

LikeLike