Pathfinder project build – End of main construction.

Blog time : as I write it is August 2022 and it’s been so warm where we live that I haven’t been able to do much work during the day outside of the workshop- especially anything involving paint and epoxy after about 8 in the morning. As it happens i’m at the end of what I consider to be the main construction stage of the Pathfinder with all of the structure built, mostly finished and painted too but with the rig to build and the detail of fitting out to do. In terms of time on the project so far I can account for around 7 months in the first year and 5 months this year plus a month to build the shelter and set up. I could probably build the rig inside of 1 more month but at the moment I wouldn’t want to be working outside with the long mast staves to glue up so it may have to wait until things cool off a bit.

Anyway, lets begin with a bit of Knolling ………. hands up anyone who isn’t familiar with the term.

For those readers who are not familiar with the term it’s mostly now used by Lego hobbyists – otherwise known by at least one model making friends as brickheads……at least that’s what I think he said. Knolling then is the pre organization of multiple parts and pieces into neat little rows and blocks of similar pieces and done well the result can look almost like a modern art installation as done with someone with obsessive compulsive disorder. My version is a slightly messier one where I just empty out the rigging bag, the parts bin and several ‘organizers’ into a big pile on the bench and roughly sort them into groups of similar fittings. If you’re really into this kind of thing then there’s even a book on the subject : https://www.amazon.co.uk/dp/0789331136/ref=as_li_ss_tl?language=en_US&ie=UTF8&linkCode=gs2&linkId=686a528bcae00d954731cfdde3461c0a&tag=thebrickblogg-21

I’m painfully aware that there is several hundred pounds worth of Harken blocks on the bench now and more shackles than i’m ever likely to need…..except for the new anchor shackles that I need for this boat of course ; generally speaking about boats and rigs – I mostly stopped using shackles years ago. Somewhere deep in my memory I was pretty sure that somewhere among the many bahs and boxes of bits there was a complete set of blocks to make up a 6 : 1 tayckle , today I can’t even remember what I bought them for but right now they, and one of many retrieved eyebolts, has just gone into the boat as the centerboard uphaul tackle.

I even found some nice little bullseye fairleads , one of which will guide the fall of the tackle back to the cockpit……right now, as I take a break, I’m thinking about where I want the running end to go and where to put which cleat or jammer…..the top of the large locker to port looks promising because then I won’t kneel on it or have to put my back against it too.

Main jobs.

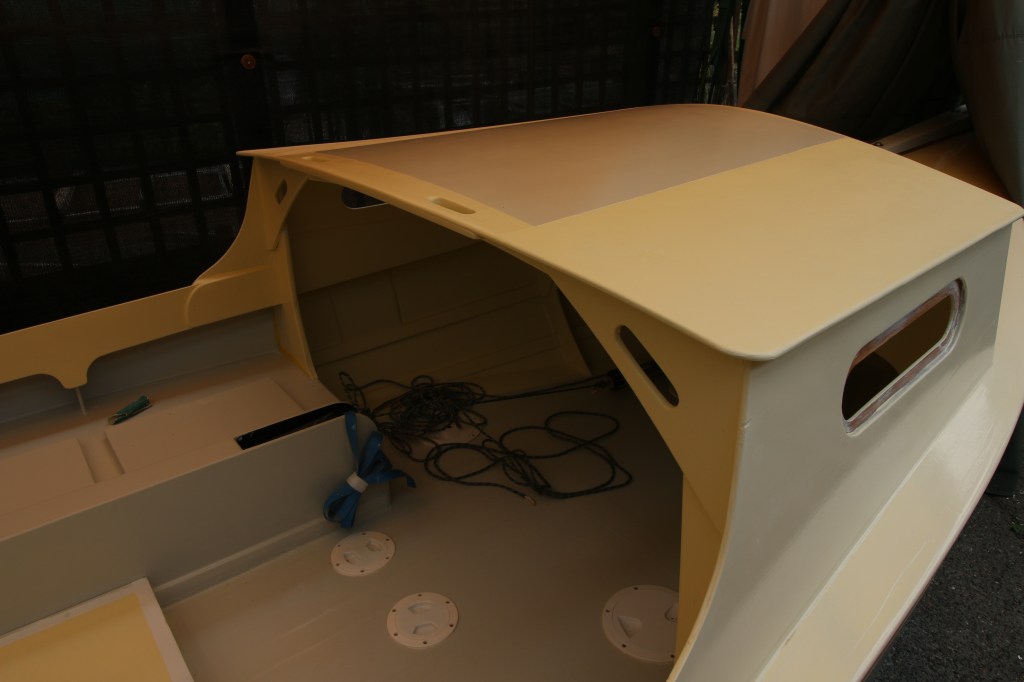

The last main construction job at this stage was fitting and finishing the cuddy roof, my great neighbour helped me with the glue stage fitting and so on the same day it seemed to have cooled off just enough to let me get a layer of 200 Gm cloth on – even with slow hardener it was still a fast job as the plywood was very warm from being in the sun most of the day. The next day I masked off a center panel on the new roof, block filled that with an epoxy and microlight filler mix, sanded that and then primed that. The sides…..each section is about a third of the cuddy top width just got non-slip coating because I might occasionally need to park my BFA there and wouldn’t want to slide off.

As a small side project I added a doubler at the aft edge of the cuddy roof and cut a couple of slot style handholds in that.

The shed roof on and painted – it just needs windows (ordered) and some nice chintz curtains now !

Buffers….adding the rubbing strakes.

My next (perhaps last) timber order was ready during early August so my partner kindly picked that up from John Moody somewhere in the hinterland of the south hams – that’s the staves for the masts with the machining done, stock for the rubbing strakes and a new piece for the boomkin. I’ll cover the mast construction in a separate post because I haven’t worked out all of the construction sequence yet so for now I just got on with preparing and scarfing the lengths of Iroko for the rubbing strakes.

That’s only the second and third scarf joints that iv’e ever made – the first one having been the two plywood panels for the bottom of the boat – and that was a year ago. That was a nice workout with two freshly sharpened planes (smoothing plane and jack plane) and then I glued them up one at a time because I clamped one complete strake to a dry piece to keep them in alignment. Today, as I write I drilled out each strake for their eventual plugs and then drilled through for screws, the more awkward job, which took two of us was dry fitting them – they’re flexible enough but springy and the boat changes sectional shape along the sheer so they have to bend and twist a bit. Iv’e left them on , after shaping the ends and will finish fit them when some adhesive sealant and better screws arrive next week I hope.

I was surprised just how much of a difference the rubbing strakes make to the lines and overall appearance……..they almost make the boat look finished and smart !

Stowing things.

I spent what seemed like a whole week just making and fitting small parts and they all take time, so far that was 2 more cleats – one more bow/mooring cleat and one for the centerboard uphaul line and then 8 chocks for the 2 anchors to sit on. I have both anchors that I intend to use and one of those – the heavy Admiralty pattern anchor now has 2 separate stowage positions so it can go either on the cockpit sole or just ahead of the ‘galley’ locker on the cuddy area sole.

Some people have commented that the cockpit stowed anchor will get in the way and that i’ll be tripping over it – I experimented a bit and what I found so far is that when i’m sitting in the cockpit my feet naturally go over the anchor position and when I stand -to row or scull – I seem to want a foot either side. Only time will tell if it gets in the way but for now it seems to be where I can best handle it. With my last boat I set things up such that I could anchor from the cockpit rather than having to clamber along the narrow side deck…..with this boat I really didn’t want weight on the bow so that precluded a bow anchor locker plus the fact that the cuddy was going to be in the way.

The yellow bag is a climbers rope bag which I am using as my anchor warp bag.

If everything goes to plan next week (as I write) then I will finish the cuddy for now but with more work to do when I get the rig done, and the rubbing strakes all shaped and on too. Quite soon now I need to lift the whole boat again and chock it a bit higher so that I can wet sand the hull topsides…..at least the top 2 panels and the deck as well and then lay the last coat of gloss on…..even being careful there are a few epoxy dobs and the odd abrasion where iv’e worked a little less than carefully.

I’ll also be setting up the build frame to use as my spar bench , as I said above I haven’t got the build sequence in my mind yet, at the same time I’m getting ready to drill through 2 layers of boat plus a mast step to get ready for the mizzen mast – that’s most likely going to be a slightly over sized alloy tube which I hope to get coated locally. Meanwhile there’s still lots more detail to do and more bits that I need so the shed door lists still get longer even though I’m slowly crossing jobs off and parts ordered.

As I come to edit the post just before it’s due to be scheduled it’s near the end of August and i’m at a bit of a loose end with the project ; the cuddy windows arrived so they are in and I finished fitting the rubbing strakes with their ends shaped and all the screw holes plugged. During the last few days of main construction – while I was fitting the rubbing strakes – I also finished, for now, the hull and deck paint and even varnished part of the transom so the whole boat has a finished look except for not yet having a mast or rudder.

At the end of the month i’m going to use all of my monthly boatbuilding allowance to buy the expensive bronze fittings I need next ; that’s the rudder fittings and a pair of bronze chain plates for the shrouds. Rather than buying nice but expensive bronze cleats I spent a couple of lazy workshop days making another batch of 6 , most of those are intended for the running rigging on the cuddy roof and one is an asymmetric cleat for the centerboard downhaul line.

The shed door lists didn’t have much to ask me to do either because the outstanding job is the mast and we have just gone through a week of sporadic thunderstorms and rain so it’s been difficult to to work on the mast outside – the rig jobs now being my main attention. That is partially why the rig doesn’t appear in this post although I have done some of the small stuff such as fitting the bowsprit for about the tenth time and making a boomkin and it’s bracket – to fit that though I have to pull the whole boat forward to give enough space at the stern and it would then be useful to do other jobs while i’m there.

Just as a little shed door joke to myself I added ‘coffee break’ to the list of main jobs so i’m doing that right now as I edit the post ready for it’s Monday morning schedule.

In terms of purely project posts there’s a couple to go because iv’e already started one about my rig decisions/mistakes and the actual build – to continue with that I need some dry and cool mornings so that my neighbour and I can set to and glue the mast staves into 2 halves. My main problem with the mast is that I will have to work outside because there isn’t enough space for the boat and the build frame – currently standing in as the spar bench – under the shelter and be able to do any work.

In terms of the main build though that’s about it for now until I can buy in the parts that I have to work around next ; that’s the rudder fittings next week hopefully then a big AGM battery next month, the mizzen mast tube, a set of oars and rowlocks and so on. That will happen more slowly during the autumn and I hope to have a complete build by the end of the year and then maybe be able to afford the most expensive single component (the trailer) in the spring and then take her off somewhere to get her bum wet.

Reflecting now about these last 2 years – the whole build has taken me 2 full summers of nearly full time work – it’s been a good project in terms of learning a whole lot of practical skills and i’m quite pleased that I have in fact built an entire boat from a pile of materials. In terms of my small boat coda it certainly hasn’t been a basic boaters cheap way of getting on the water – almost any cheap secondhand boat would have been better for that because it’s been and continues to be an expensive project.

I think that the project has done me good just in terms of the everyday problem solving that iv’e had to do, I don’t specifically want to be a backyard boatbuilder but I would like to get on and start to work on other projects ; one of my developing interests is to have personal transport again – i’d quite like to have an old motorcycle to tinker with and rebuild but my main interest would be a partially electric assisted 3 wheel ‘tadpole’ trike.

A lot has changed in these last 2 years ; I note for example that my other posts on the blog are taking on a darker although internally logical direction – to me it feels as though ‘the party is over’ – maybe for a project post I should just leave it there aside from a few lines from T.S Elliot’s poem ‘the waste land’.

Gentile or Jew

O you who turn the wheel and look to windward,

Consider Phlebas, who was once handsome and tall as you.

Right smart that is Steve. “Consider Phlebas” is a good 80s space opera novel by Iain M. Banks, but you probably already know that. He got even more mileage out of “The Wasteland” by calling a much later book set in the same world, “Look to Windward”.

LikeLike