May we begin .

Marking out and making patterns.

SQD Pathfinder build.

Blog time : it’s May 2021 iv’e finished the main construction of the outside build shelter and i’m just waiting for a day of high wind and heavy rain to find out where the weather will come in ; that’s ok because i’m planning on hanging scrim net inside and a drop-cloth at the front anyway. The plywood for the build is all here as is the stock to make the centerboard lamells from and the first batch of epoxy resin too……so it’s time to begin making parts i feel. In April i had a go at melting and casting some lead for the centerboard because i thought i might make that first although having thought about it all a lot more i think i will work in a more logical order and start making the frames…..or at least making some patterns for the frames and working out how best to lay them out on the plywood sheets. Including the transom and some half frames iv’e got 7 frames to make although several of them seem to be most efficiently made from several pieces glued together rather than marking out and cutting them out as a single piece. This post then will be all about me learning how to make the patterns and then accurately mark out, cut out and construct the actual frames : i reckon to allocate all of my working time this month just to that job so…..

On the bench – April.

In line with my new post layout i’ll show you what i did with my project time during April and as i explained in the last pair of project posts , with more pictures and less text.

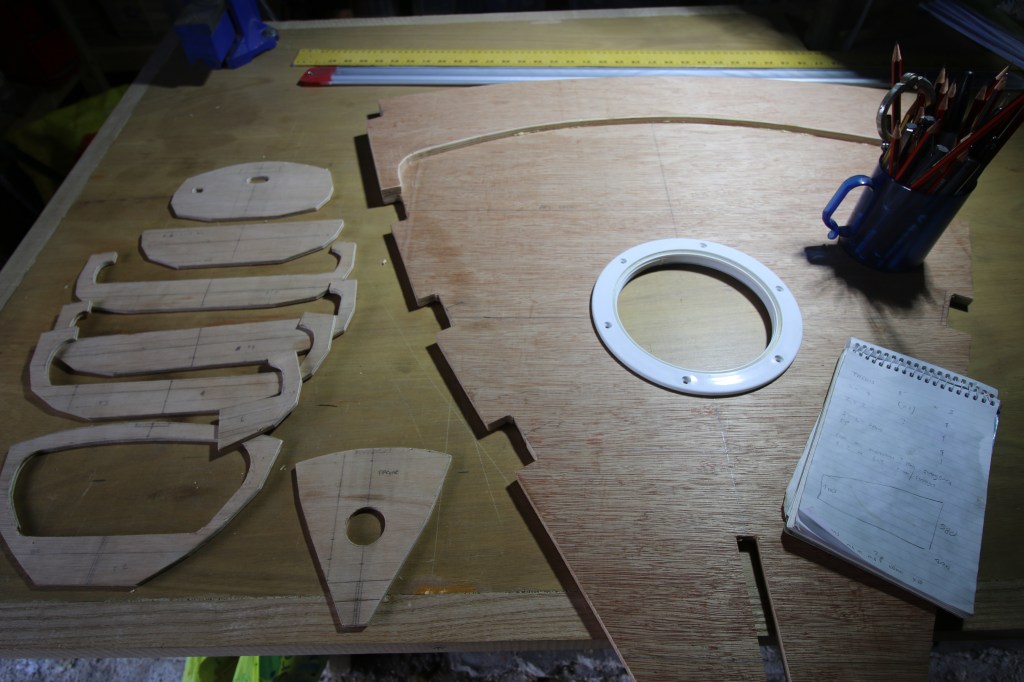

I haven’t shown this side of the project before so i’ll explain that first : that alongside the main project of building the actual boat i’m also working on a 1/6th scale model to both help me understand the shapes in 3 dimensions and to play around with the modifications in model form before i commit to them in the actual build….some of those things we have discussed in the designer’s social media site and the latter one another member sent me some nice pictures of his version . On the left then are the 6 frame models and transom at 1/6th scale and on the right is the full size mock-up of frame number 1 complete with it’s deck doubler and inspection hatch but minus the forward face stringer doublers.

I won’t use the frame No 1 mock-up as it’s only internal use plywood and i only made it just to see how i got on with interpreting the drawings ; the model frames i may well take to a complete model that i can mess about with.

The XY plot.

As iv’e said before i’m not a boatbuilder and only a poor woodworker so don’t take this as an expert showing how something should be done, rather it’s me putting across the process i’m going through in learning how to do this and maybe in that process demonstrating the most basic things that another beginner would also need to learn so…..

The complete boat looks quite curvaceous but it’s actually built up from a series of curved planes, thus not curved in 2 planes at once ; the bottom of the boat for instance is essentially a flat piece of plywood that curves up at either end but flat across it’s width….then, the frames that mount onto the ‘flat’ base also have a straight-edge base and their sides are a bit like a 50 pence piece in that there are several panels and chines but each panel lies flat in it’s own plane across each flat/straight section of frame.

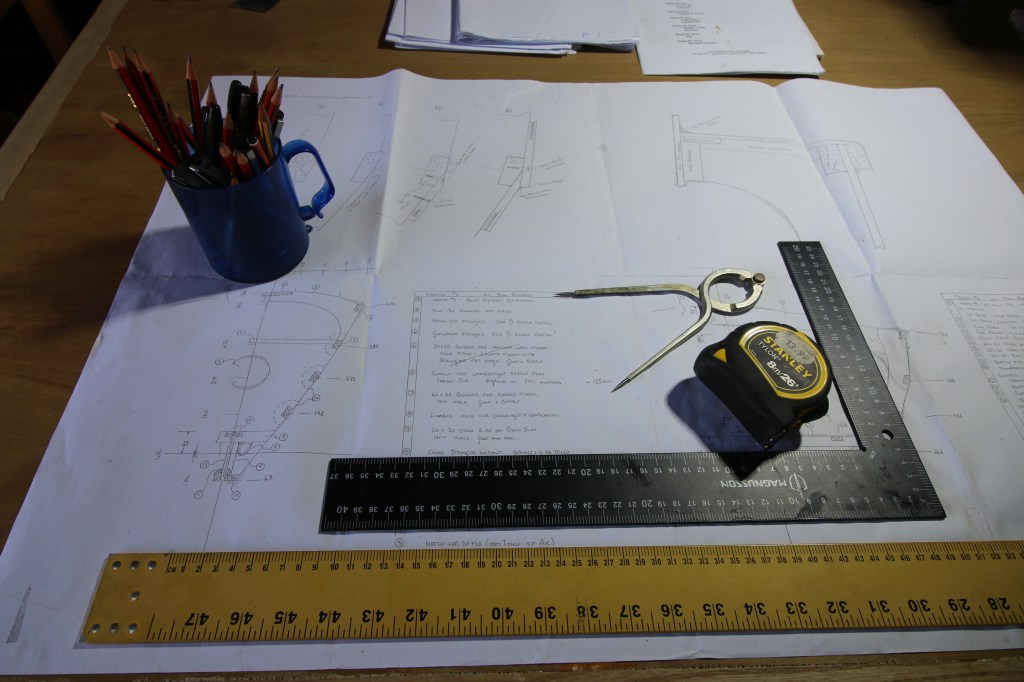

Each frame then is basically drawn and cut as a series of ‘XY‘ points (if you think in graph terms) where one axis is determined by a common datum line, in this case the waterline and where the vertical axis is the centerline of the boat. All of the chine points are thus marked as distances ‘across and up’ (or down) from the waterline and centerline thus : (below) the parts that aren’t straight lines are the line of the deck at the crown of frames 1 and 2 and similarly with the curved top edge of the transom. I’ll show separately the marking out of the curve for the deck line of frame no 1 and talk a bit about the other curved edges which aren’t defined in the same way by XY points in the drawings.

My plan is to make a pattern of each frame first , in fact to make a pattern of each piece of each frame first before i mark out the actual frames on the plywood that they’ll be cut from. The reason i’m going to do it that way is so that i can use the frame pattern pieces laid out on the plywood to help me see how best to use the panels. There is a comment in the drawings and instructions from designer John Welsford that the frames can be made in one piece but that then uses more wood. For now i’m going with the plan of making the frames up from separate pieces (frame no 2 starts with 5) but if i run into problems i might do that frame in one piece and just risk maybe having to buy another sheet of ply. Very fortuitously the packaging material that my shed roof came in looks like a useful material to make the patterns out of : it’s a bright orange clear plastic almost like a bi-layer that seems to be stiff enough for the job. I also acquired a couple of sheets of what i think is 3mm MDF or similar that were came on the truck protecting the plywood.

Good luck with your build.

I am enjoying your account.

As an aside, did you consider a cat or tri?

Regards

Graham

LikeLike

In the past i had one small cat (Wharram) which i learnt a lot from, Friday’s post (i think) covers one of the boats that i considered which is effectively a small Tri.

LikeLike