SQD build post 1.

Pencil to wood.

Making mistakes…..lots of mistakes.

Blog time : it’s the beginning of April and by an unfortunate coincidence day 1 in the shed just happened to be that day and it turned into an entire comedy of errors as i started work on the first full size mock up of frame no 1 for my Pathfinder build project. You see, in blog time i don’t have the actual boatbuilding materials yet although what i do have is some sheets of plywood left over from our bathroom rebuild project a couple of years ago and i figured why not just use some of that just to learn how to do the basic processes of marking out parts, cutting them out and assembling at least one of them …..and so the mistakes began. As i write this, now a week further on, i have actually made a full size mock of that first frame which is the mostly triangular thing (with) chines, that’s now sitting on my workbench, i’ll never use it because it’s inferior ply whereas the actual plywood is much higher quality but that’s somewhat irrelevant because i did this process as a learning exercise only and boyo did i learn a lot so in my terms it was a success.

There’s a few things that i want to get out of the way first and then i’d like to explain what i’m intending to do with the blogging side of this project so……

Firstly though i must emphasize that i’m a retired nurse and not a boatbuilder or even an amateur woodworker of any kind so in one way i am exactly what designer John Welsford had in mind when he drew the plans and wrote the instructions for the build process : somebody who wants to build a boat, has time and enthusiasm but little in the way of practical skills or knowledge. I have to keep reminding myself that i’m trying to build a small seaworthy cruising dinghy at a good ‘working boat’ standard and not a stradivarius or grand piano level work of art – if i give it my best shot and i’m diligent and conscientious about my work then i have a chance of achieving that. I did have a basically sound education in formal woodwork but that was 50 years ago and even then i severely tried the patience of my late woodwork teacher …….perhaps one of the best teachers i ever had and one of the rare good memories i have of my school days…..which i mostly hated with a passion !. Usefully then i have basic hand tool skills but very little experience with woodworking power tools although frankly i don’t have the space for the kind of power tools that would be most useful – a table saw or bandsaw for example : we actually had one of each in the woodwork classroom and i used both a couple of times…..and then of course we had a much bigger and scarier one at the boatyard, not that i ever got to use it . As useful is that i also took the complementary class to woodwork, both optional, which was technical drawing so i can mostly look at a drawing and see what the designer intended.

My plan of work.

By the time this post goes live i should have both the first batch of boatbuilding materials and what i need to put up the frame for my boatbuilding shelter : in the case of the actual project materials that’s all of the plywood, the hardwood for the centerboard lamells and a first batch of epoxy resin. On the ‘bob side it will be a load of rough treated 4×4 posts, 2×4″ rails and the sand and cement – iv’e been saving bucket after bucket of small rocks and stones from the garden for the ballast for those.

Some time during April then i will be putting pencil to actual wood for the first time and be making the frames and bulkheads for the boat, as a separate project i’ll be making up the blank for the centerboard. Alongside that or in parallel i’ll be building the outside shelter for the actual construction stage. Looking at John’s plans again suggests building the strongback/frame first but that’s going to be in the way until the shelter is up so that’s only going to happen just before i need it which i think will be around mid-summer this year.

Blog work plan.

This week i tried to film video clips as i was working and just sitting at the bench being a bit of a ‘talking head’ – hardly the stuff that makes for good video, a medium iv’e never got comfortable or competent with. I think that what i am going to do is write up and photograph each stage and each process in the build and i hope that will then become a useful written and pictorial guide : i do intend to shoot video clips as well but more along the lines of short ‘talkies’ when i feel that will put across what i can’t achieve as well just with still pictures and text. I’m also working on finding a format that works well and that visitors become familiar with – the kind of thing i’m thinking is organizing the text and photography into tasks on the bench, admin jobs, notes on processes and tools and finally problems encountered/solved and lessons learned. What follows in this post is a first take on that so :

On the bench this week.

1 .Mock up/full size model of frame no 1 marked out, cut out and assembled with it’s deck doubler, time taken about 6 hours.

2 .New LED light bought and fitted over main bench working area, time taken 2 hours because i had to walk down to the shop twice to buy a plug for it……closed for lunch of course.

3. Studied plans for construction of build frame….’free’ time as i sat at the bench having my coffee at the same time.

4. Took apart my non square drywall ‘square’ to make a temporary straight edge and ruler.

5. Spent about 2 hours breaking down an old lead acid battery for the lead….2 to go.

6. Finishing bench with a hardwood edge……about 2 hours.

Admin time.

- Confirmed order for the first batch of materials with the timber merchant, tried to make a card payment which failed (twice), then couldn’t set up a BAC’s payment so i had to get on the line and wait to speak to the bank help desk (40 minute wait) and then spend another 20 minutes going through security checks and having my account unfrozen.

- Spent about an hour online searching for a nice long straight edge/rule that isn’t a bright stainless steel and with numbers that i can read ; two of this week’s problems being my current straight edge only having ‘thick’ marks at 2mm spacing and not being able to read the super-fine markings on my smaller engineers rule. I also struggled with light on the bench …..below.

- Filmed, downloaded and edited several hours of video work, took some photographs and spent about 5 hours trying to create usable video content…..binned most of it.

- Researched and ordered a propane burner torch for melting the lead for the centerboard ballast weight.

- Ordered a whole load of different grades of pencil to try and work out the ideal line weight for marking out.

Processes learnt and tools used.

This week i put pencil to wood for the first time on this project and yes, that’s where most of my mistakes happened : my task of the week being to mark out the datum lines on a piece of plywood and then from those 2 lines mark the XY points that form the points of the chines…..the piece i was working on being a bit like a triangular 50 pence piece. The first tasks then were to mark a straight and true waterline (datum line 1) and on this piece a centerline (datum 2 line), the marks for the chine points are then measured up and across from the 2 datum lines. My main mistakes were firstly that i took the widest half-breadth measurement and the marked length of frame no 1 (from the plans) as being the size of the piece of plywood that i needed. Of course it became quickly apparent what i’d done when my marks went off the piece at the second stringer notch point and that was my first noob moment. My second mistake was that i’d folded that drawing across the center so that i could have it on the bench and what i failed to see because of that was a set of numbers at the top of that drawing that gave the measurements for the line of the deck – it being a nice curve and not a straight line. My initial marking out wasn’t great either because i tried to do it in the way that my old woodwork teacher taught us for technical drawing which was with a fine line first using a ‘hard’ pencil (4 H) and only when sure of the line marking over it with a darker ‘cut’ line. One problem i had with the marking out was very strong sunlight from the open door of the workshop at such an angle as to create a hard shadow next to my straight edge, aside from that i simply read some of John’s measurements wrongly and that became apparent as soon as i drew the cutting line……no great problem and just a case of adopting the ‘measure twice, cut once’ rule.

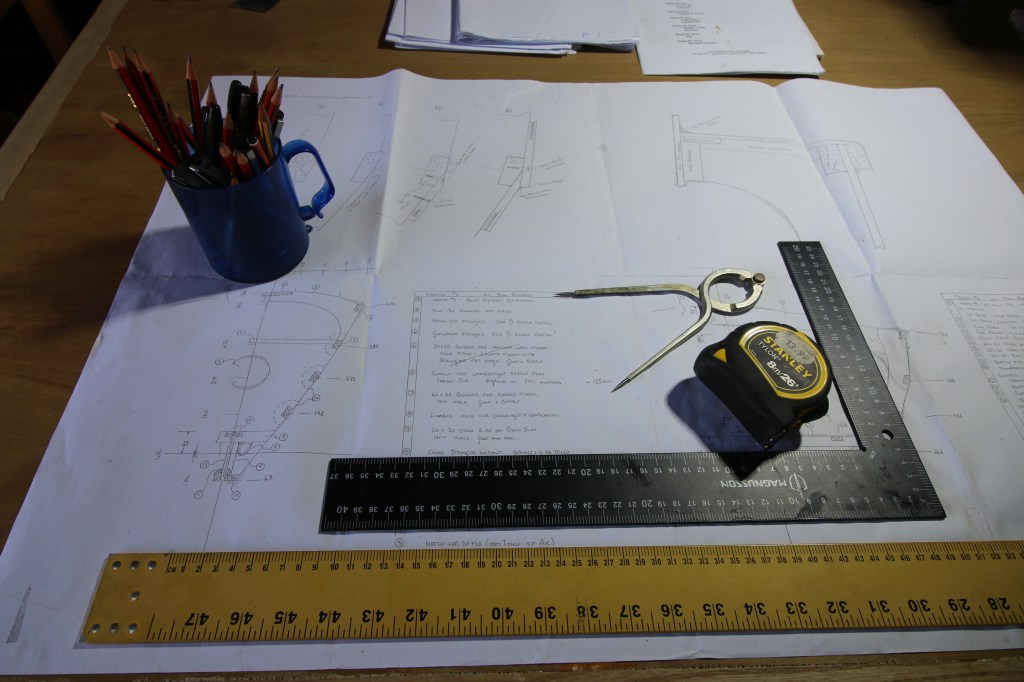

Long straight edge, marking out square (actually square !) steel tape measure, dividers for picking up small measurements, lots of pencils. Drawing in bottom left is frame no 1 which is what i was working on.

Practise is very very important, I leaned a lot by making templates from 3mm MDF. Cut em out of whatever, trace onto a back sheet, again 3mm MDF is great, then flip em round and check for symmetry errors are immediately apparent unless of course you made the same error twice. Measure and mark out the frame on your ply from the drawings dimensions then lay your pattern over the ply to triple check. It’s worth the time so as not to waste BS1088 and precious hours of your life. Finding an error this way is a reward in itself.

LikeLiked by 1 person

I keep making a mistake , done the same thing several times now, in that there are several numbers and marks all close together on the drawings and i seem to ‘pick up’ the wrong ones for the chine points. One thing i might do is make myself a simple table of the XY points for each frame first and then only check with the drawing just before cutting.

LikeLike