Pathfinder project post June 2023.

This week both us have been shopping (my partner and I) and both been shocked by how much prices have increased in our respective shopping baskets : my partner does the weekly shop while I usually cook our meals so she saw the huge increase in food prices while my shopping was down at the local jewellery store (chandlery) and I was honestly shocked by the price of some of the fittings I need.

With the Pathfinder project i’m at that point where I really have to buy ‘stuff’ that I think I need and which I can’t reasonably make myself – I cant ‘make’ modern multi-strand and multi-plait cordage because that really needs a high end machine and nor can I make high-end ballbearing sheet blocks. One of my questions then this week was to ask myself whether I really did need high-end ballbearing blocks and/or some of the other fittings that I feel I need to complete the build ; well, the answer seems to be a partial yes, partial maybe and maybe more likely the ‘third way’ of opting for simpler solutions and to doing as much as I can with materials I have laying around in the workshop.

To jump to the car chase and sex scene then here is one way that I saved a shed-ton of hard cash during the build and it was through the simple expedient of learning to make an Ash cleat and then working out a method of making lots of them in one go. Iv’e now made and fitted 15 simple Ash cleats – I really had to think there for a moment because there are 6 mooring cleats, 6 halyard cleats on the cuddy roof and then a few odds-n-ends scattered about. Now, my original intention and desire was to have cast Bronze cleats to go with the cast Bronze rudder fittings and chainplates but a single cleat of the same size as my spring/anchor cleats is upwards of £35 a pop – so that would have been 15 x £35-£40 and I haven’t even bothered to work that out. As it is just fitting the rudder with gudgeons and pintles was a £200 + job and the chainplates a cool £40 each but I consider both of those money spent necessarily on crucial components.

Cleats and anchor chocks made from a stick of Ash bought to make canoe paddles from and some unused Sapele bought for the centerboard construction. The greater cost with the 15 cleats are the 30 stainless steel mushroom headed bolts to attach them with and the stainless steel nuts to fasten them with.

Yesterday though, in blog time, I went into town for a shopping spree at the working boat chandlery, then the posh yachting chandlery and finally to the professional rigging store on a hunt for blocks, jamming cleats , cordage and other fittings. Yesterday’s haul was mostly a whole load of the stainless steel eye-straps for tying and lashing in loose gear and a speculative look at the blocks and jamming cleats I will need for the mainsheet and jib sheets. Once home again I set to with the various strap-eyes and lacing hooks but mostly failed to fit out the forward end of the cuddy space under the foredeck in the way I had visualized….no matter though because those fittings came straight out again and the experience suggested a better plan anyway.

The shock though was what seemed to be a massive increase in the cost of high-end stuff such as nice Harken blocks – I quite like their blocks having ‘Harkenised’ my previous boat, the little cat-ketch rigged Liberty who’s blocks were stiff, knackered and running badly (ok…just like their owner). Thus the cat ketch got it’s mainsheet arrangement , it’s snotter tackles on both main and mizzen and all of it’s deck lead blocks replaced, over time, for nicer Harken ones and that actually improved the sail handling and actual sailing of the boat. On that boat, by the way, I also continued my experiment with low friction rings used in the place of blocks – they worked well so the Pathfinder already has some doing the same jobs as they did on my previous boat.

The shocking-est part of the whole chandlery experience was the cost of just the few Harken blocks I would need just to make my intended mainsheet system and on top of that the additional cost of the Harken jam cleats – the simple upshot of that is that it’s not going to be a Harkenised boat….but there again it’s a working boat style boat and not a ‘look at me’ high end racing yacht with all of the bells, whistles and matching crew uniforms.

Low friction ring lashed onto the bowsprit as anchor lead – and if you’re wondering that’s for an all-warp or mostly warp anchor rode.

Working on…

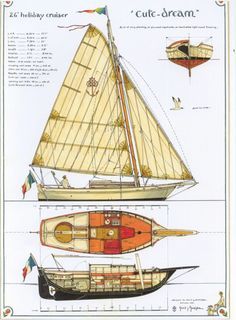

Right now, again in blog time, i’m just taking a coffee and writing break in between shaping and gluing the pieces on the workshop bench that I hope will become my experimental laminated gaff saddle and rocker block combined and the reshaped gaff spar end. The reason why there are 2 gaff saddle/rocker block assemblies on the bench is that the forward one is the actual one for this gaff spar while the one behind I am making for a potential curved gunter rig that might be the basis of rig 2 for the boat. While right now I am heading towards completion of a fairly conventional gaff sloop it might in time become a cutter with a larger stays’l, smaller balance jib on a longer bowsprit and with the curved gunter mains’l similar to one of the late Daniel Bombigher designs below.

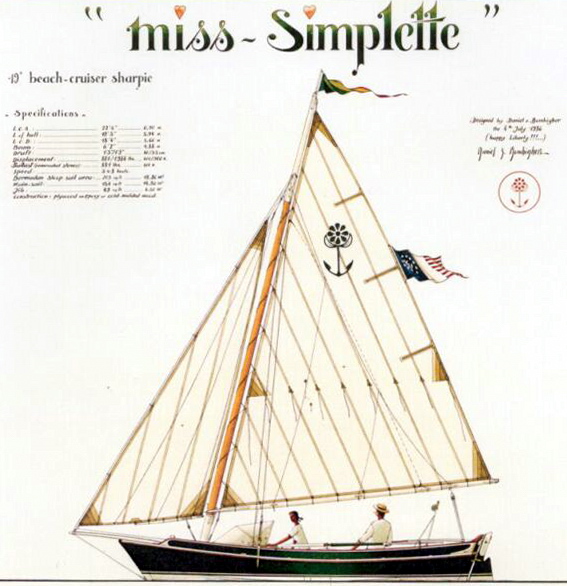

In terms of raw cost the whole rig so far has been a surprisingly economical and enjoyable project – I made the hollow mast tube in birdsmouth construction although I have to admit to having the birdsmouth’s machined during the preparation of the staves at John Moody’s timber yard. Even with the reasonable cutting and machining costs, which I thought would be high, I found it a surprisingly inexpensive way of building a mast and my recent thoughts have been drifting towards building a second one but taller and lighter for something like a ‘Simplette’ rig (below)

The simple working boat.

I think I always knew that I wouldn’t be able to build a perfect miniature superyacht but with maximum effort I might get close to a good standard of working boat crossed with an expedition boat – like, for example Howard Rice’s well thought out and highly detailed SCAMP design Southern Cross. That thought is still there and that is mostly what I have achieved except that I have dialled back on the expedition boat a bit recently, partially due to cost and partially because I have gone towards simplicity and ‘simple’ functionality ; to explain what I mean by that allow me to recall a recent experience .

Earlier this year my partner and I took a short break with a camp just near the English seaside town of Weymouth and during which we went to scout out the slipways at Portland – one of the venues I have in mind for our maiden launch. While there that day we had a short day-walk out along the Flete which is the tidal waterway behind Chesil beach and potentially accessible to my boat by passing under the road bridge that takes the main Portland road. I’m not sure of the air clearance under that bridge and it might be close to my boat’s maximum air draft so it’s not the normal kind of place that the average yachtsman would think about as a bad weather hideout…..most boats simply couldn’t get in there.

Last year I had several changes of heart and mind when it came to WABI IV’s rig and I went from the ‘simple but performance rig’ that I originally intended ( a west country/Breton style lugger) to a rig who’s main characteristic is to get the mast up and down on my own whenever I feel the need. One side of that is that I can rig and un-rig the boat without any assistance, one of the results of which is that I should now be able to pass, fairly easily, the road and rail bridges often found at the head of navigation in may rivers or for example on the Norfolk broads.

In a different aspect of the boat’s set up iv’e recently had another change of heart and mind so…..

One of the features on my list that I felt would take my boat from day-sailor to full-on expedition boat was a fixed electrical system with a large AGM battery also functioning as the boat’s main ballast – 60 Kg of it. That would have been charged by a solar panel each side of the cuddy roof , backed up by a ‘smart’ charger at home to keep it topped up. As you can well imagine a battery of that size has a certain cost but the whole costing for that project also includes a pair of solar panels, an isolator switch and MPPT unit, then a switch panel and finally the wiring and accessories before even getting to the equipment that the system would power.

My thinking behind all of that is that a fixed VHF radio would be a good idea and given that the technology is there the fixed VHF could also contain the GPS and nowadays an AIS system – of most use when crossing the channel separation lanes at night in a small boat. It would also mean that the boat could have ‘legal’ lights at sea although in practice I can almost get away with a single white light due to the length of the boat, when it comes to anchoring I use a 12v camping lantern hoisted into the rig and lay at anchor for 110 nights in Brittany with no comment or complaint. The other thing that a large battery is useful for is it’s ability to run my power hungry Macbook while i’m writing, which is something i’ll do at sea next time around as well…..well I would were it not for the fact that my Macbook has spat it’s dummy right out and I suspect needs a whole new battery itself.

Last week I realized that i’d made one significant mistake when it came to the boat’s electrical system and a more major one when I looked at the intended battery compartment and realized that I hadn’t ballasted the boat ; the minor mistake is that I hadn’t made provision for a VHF cable and a power cable inside the hollow wooden mast when I built it. That would have been an easy thing to at the time and if I build a second mast i’ll definitely fit both as I go along.

This week though made me think more about my intentions and priorities for this year and that is most definitely a boat that can be rigged and un-rigged, a boat that can be sailed and anchored easily, one that can be made to be comfortable while living aboard and one where all of the gear is securely lashed in. One of the most essential things I have to do right now is to ballast the boat so this weekend’s main jobs is to find and secure as many Granite blocks from the garden as I need to match the designers suggested requirement for ballast. It’s quite a neat job as well because I have a stack of shaped Granite blocks that were once parts of the Royal William shipyard down at nearby Devonport.

Question….how many blocks of granite does it take to match a 160Ah AGM battery ?

Well, the better answer is to ask a better question because even I could just pile up a load of blocks until I had my required weight but the much better question was how near I could get to my desired ballast weight using the battery box and as many blocks as I could fit in there. That answer was 6 blocks and their total weight is just over 47 Kg so that’s close enough to the designers suggestion of a bag of sand each side of the centerboard case. What that means is that I can get on with an essential job right now and leave the entire problem of fixed electrics or not to ‘future’ Steve.

In the future I happen to think that having a big battery as ballast is still a good solution because it’s a bit more weight and it has a useful function one day even if it’s a while before I can use that function. In the meantime I can get on with finishing the box, securing that into it’s compartment and fitting it’s partial bulkhead which in turn will create the main ‘dry and heavy’ storage compartment in the middle of the boat.

The last part of my thinking about doing as much as I can for myself with simple materials this week is to not buy a set of conventional fenders and fender sox but to make one piece of kit do 2 or 3 separate jobs ; my plan is to take the old pair of camp thermarests which might function aboard WABI IV as seating and to give them a second use as additional buoyancy and a third use as soft boat fenders. I won’t use them in that role very often and to be honest I don’t intend them to take much pressure so my plan is to make a simple set of heavy duty covers/bags from them out of some scrap polyester canvas and hang them on the outside as and when I need fenders….otherwise stuff them under the side decks and tie them in as buoyancy.