Ballast and stowage for the Pathfinder.

More small detail jobs

Still no sails !

“The moment that you say of a boat ‘job done’ is the very moment that you need to give yourself a good kick”

Last week I was complaining a bit over the fact that I had run out of jobs and was all ready to go out on the road once the sails arrive – well, since that moment iv’e been doing this little job and that little job, not with much to see but all essential details that really need doing before we sail the boat. Today for example iv’e been dealing with the simple task of lashing into the boat everything that could move or fall out of the boat if the worst happened and we had a capsize. As it is I do know that at some point in late summer i’m really going to have to talk another local boat owner into overseeing a capsize drill.

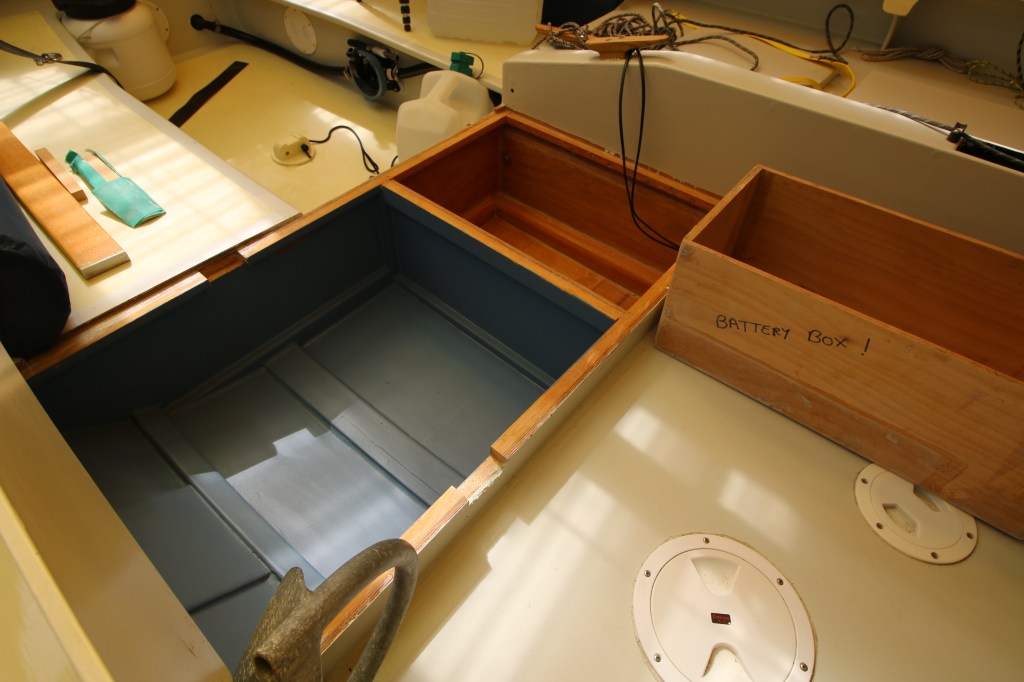

Today then I started to deal with the temporary problem of ballasting the Pathfinder – temporary in that I have a long term solution for her fixed ballast which involves a 60 Kg AGM battery in it’s own dedicated battery box in the middle of the boat and up against the centerboard case. I haven’t taken the long solution yet because I don’t have the battery yet and nor do I have a system built for charging it or an electrical system except for the wiring I put in place during the build. That whole job will cost around a cool thousand (GBP) so it has to wait until iv’e paid for sails, all the fittings they need, an outboard motor and several yards of fabric for bags and covers.

The designer (John Welsford) says in his set of build notes to at least ballast the Pathfinder with a bag of sand each side of the case but given my asymmetric board layout I now have a large central storage compartment to stbd of the case and a smaller but taller one which is going to be the boat’s primary food locker. Later this year the already built battery box will go in that compartment right up against the centerboard case so that weight (60 Kg) will be both low and in the middle of the boat. Outboard of that to stbd will still be a usefully large storage locker where anything heavy will go…..in time that will be the tools, spares and suchlike….and on longer trips also be the ‘heavy’ larder.

Today’s ballast experiments.

I intend to carry my reserve drinking water (20 L) as a pair of 10 L containers at the forward end of the cockpit, I laid out the anchor stowage around that plan and today did the essential job of finishing the anchor lashings and the tie-down points for the 2 water containers. I know that other sailors object to the cockpit floor stowed anchor but it’s not been a big problem while iv’e been experimenting with sitting and rowing positions and it does also have a second dedicated stowage position under the cuddy if it really annoys me.

That leaves me about 40 Kg short on ballast so today I messed around with additional water ballast in the form of one British Army jerry can (20 L) and a spare bag of cement that I had in the workshop…..for obvious reasons that made me grin a bit as in any problem the combination of water and cement inside the same space are 2 of the components of a block of concrete in a space that might behave like a cement mixer in a lively sea. A better choice would be a trip down to the builders merchant and just get 3 bags of builders sand which I could then double bag and lash in place in between the bilge chine stringer and the centercase log.

Anyway……scotch that as they say….!

This week kind-of turned on it’s head when I realized that I was going to have to report, once again, that I still haven’t got the sails and nor have we scooted off down to the coast to launch the boat. So instead I started filming a completely unscripted video blog while I got on with the last main construction job on the boat…..which I should have done at least a year ago but didn’t because of a delayed decision. One thing that iv’e been bad at during the build is leaving some decisions until some unspecified ‘later’….down here we call it doing jobs ‘dreckly’ (Cornish term) and so it was with the battery box and center compartment.

So….this week I just got on and finished the center compartment to as ‘done’ as possible at this stage with it’s dividing bulkhead all trimmed and fitted, the ‘floor’ (sole) bearer fitted and the compartment lid bored out for a pair of access hatches. The center compartment top, which forms the combined center seating position, cooking station and navigation table is now dry fitted for now and i’m going to load the battery compartment with dry ballast for now – I worked out that 6 blocks of Granite from the garden fit the actual battery box nicely and come in at 47 Kg which will do for now.

Small jobs.

For most of the week I carried on doing small detail jobs such as adding lacing eyes and strap eyes everywhere that I had to tie something in or down…..so far : water containers, anchors, loose gear aft, thermarests and even to the extent of making a pair of natty little chocks to take the looms of the oars. Part of that is about thinking ahead because I think I had to lift the oars off the aft side decks for the boat’s likely mainsheet arrangement.

Different approach….

As the whole background to this week’s though is the completely different approach to work and blog this week in that instead of writing a post (this post) first I basically sat in the workshop between sessions of shaping and gluing and did a completely unprepared and therefore unscripted video. Most of that turned into a video chat about the development of this boat as an expedition boat and the actual short work sections I layered over what would otherwise a boring ‘talking head’….mine of course.

It was an extremely long night after that because basically I had to sit up for 8 hours with the computer while it rendered and then slowly uploaded the new video….the combination of a weak broadband connection here and an old and cranky computer (like it’s owner) does mean that sometimes it will just stop uploading and go to sleep leaving the job unfinished and it’s screen frozen.

I was surprised when it actually finished the job at around 0300 and went to bed myself but then completely stunned when I got up a few hours later to find it heading towards a thousand views on the first day ; that has never happened before and to be honest iv’e always been happy when one of my short video segments gets a few hundred views over a few weeks. The end result is that I felt I had to start filming again almost straight away to explain and correct some of the things that I said in that piece….I suspect that what i’ll end up doing is a weekly video blog rather than the short Friday post that iv’e been doing because within that I can show jobs quite quickly an layer those over me having a chat about anything to do with the boat or my main blog posts that week.

Here’s the video by the way.